Leader in

rubber granulate mats production

REKOPLAST Kompozyt is a Polish manufacturer of rubber granulate mats and flooring.

The company is a subsidiary Recykl S.A. Group listed on NewConnect, which collects and processes automobile tires through its entities and produces rubber granulate and powder.

REKOPLAST was established as a combination of Recykl Group’s resources and expertise and the Polish company EPP Pro Plast, which specialises in making products of compressed granulated rubber. The aim of REKOPLAST is to develop and implement innovative technologies to manufacture unique composite material based on regranulate.

Backed by full support of its shareholders and the capital group and using innovative and fully automated machine resources, REKOPLAST makes unique rubber composite mats and flooring based on its proprietary formulations. The properties of composite materials developed by the company’s team of engineers can be modified and tailored to our customers’ needs.

Our technical facilities and unique relations with the partners behind REKOPLAST as a project allow the company full control over the entire production process, including influence on the production parameters of the rubber raw material processed by other group subsidiaries and used for making rubber mats.

Thanks to its unique business links, REKOPLAST not only can produce mats and flooring with consistent repeatable technical parameters, but also continuously and quickly improve its own products.

Ground-breaking manufacturing technology.

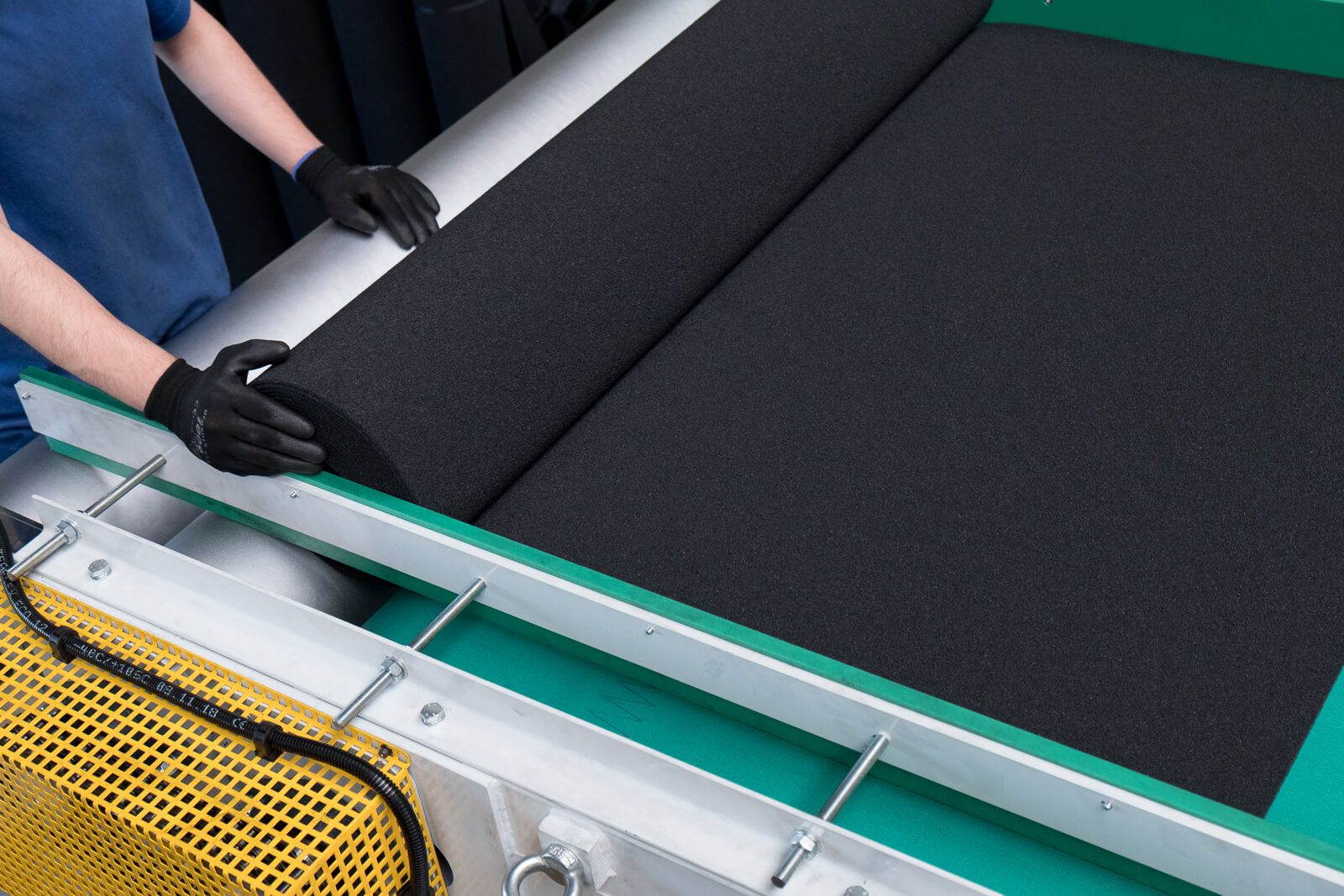

The REKOPLAST facility in Ocieszyn (Wielkopolska Province of Poland) has built machinery resources from scratch in order to be able to implement its innovative technology. The production line is located in a 2,500 sq. m hall and is fully automated. At its heart, there is a machine that – in keeping with REKOPLAST’s tradition – was given the lovely name of “DOROTA”.

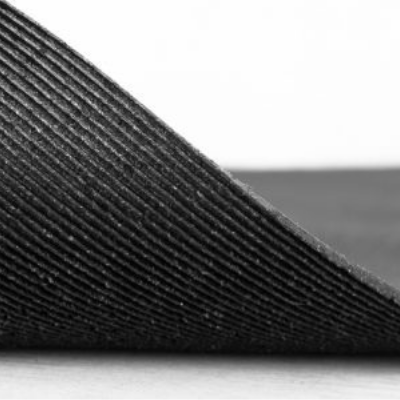

At the plant, rubber granulate of an appropriate weight, cleaned and sieved, is dried and mixed with polymers. Under the influence of heat, the polymer surrounds the granules, fusing them together. This results in a composite material that, when mixed properly, forms a plastic mass. The mass is calendered and pressure shaped before cooling for the intended use of the finished mat.

The entire production process is carried out in a continuous manner. It is strictly controlled in terms of accurate technical parameters, with a strong focus on quality monitoring. As a result, the company makes high-quality reproducible rubber mats.

Moreover, a thing that makes REKOPLAST stand out is that any mats leftovers from seasoning and cutting are reused. This makes the company production process completely wasteless, and REKOPLAST branded rubber mats are 100% recyclable.

Unparalleled properties of our mats.

Our unique method of production translates into unique properties of the mats.

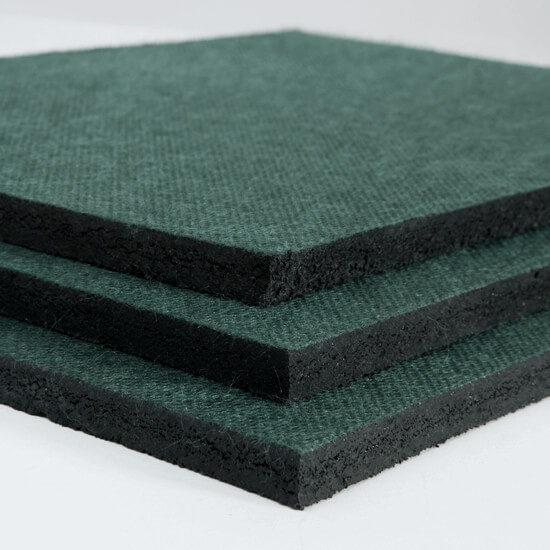

First of all, REKOPLAST rubber tiles and mats are very durable and have favourable physical and mechanical parameters.

The mats are flexible and have good elastic recovery. At the same time, they are characterised by high rigidity and tensile strength.

The tiles and mats are also highly resistant to abrasion. The polymer that binds SBR granules protects them from UV degradation. This makes REKOPLAST products weather- and water-resistant. The mats are suitable for all applications requiring sound insulation and reduction of vibrations. The use of polymer bonding agents for rubber granules enables us to achieve a level of sound and vibration isolation unavailable to solid rubber panels or granules bonded using other methods.

Operating in compliance with the applicable regulations and requirements, REKOPLAST takes full responsibility for its products. Their parameters and properties are confirmed by tests and certifications. Our rubber mats comply with the ROHS directive and REACH requirements. Following a range of tests at the National Institute of Public Health, the products have been certified by the National Institute of Hygiene (PZH) to be free of hazardous substances.

REKOPLAST products took part in the “Produkt w Obiegu” (Product in Circulation) competition arranged by the Polish Ministry of the Environment to promote environmentally-friendly achievements of the Polish industry and were presented at the POL-ECO SYSTEM International Trade Fair for Environmental Protection in 2019.

Broad range of applications

REKOPLAST products are used in the construction industry as protection for roofing membranes, screed underlays and protection against mechanical damage. They ensure acoustic and vibration insulation for floating floors and are also used as a base layer under floors. They are also used for soundproofing in partitions and mobile partition walls.

They also meet flexibility and durability requirements for sports surfaces. They are applied as protective mats for ice rinks, gym floors and fitness rooms, where they provide anti-slip protection and fall protection.

Thanks to their good grip and cushioning properties, they are used in industry, for example as wet and dry matting on assembly and production lines, where they improve comfort for people who work standing for long periods of time.

The mats also effectively secure loads in transport by protecting them from impacts and preventing them from shifting.

The range of applications for REKOPLAST products is as broad as the available options of their density, shape, texture and colours thanks to admixtures that modify the appearance of mats and tiles we make from our unique composite material.

As SCP, we are proud that after many years of cooperation, this innovative manufacturer trusted us to become the Exclusive Distributor of REKOPLAST in Poland.

We are pleased to be recognised and awarded the title of Exclusive Distributor of Rekoplast on the Polish market.